Guardian-HD Elite Web Profiler

Advanced Features, Central Monitoring of Single or Multiple Systems

The Process Sensors Guardian-HD Elite Web Profile Analyzer is a rugged single- or multiple-scanner system used to measure moisture, coat weight, and temperature (optional) for all paper, film, and web-converting processes for both wet- and dry-end applications. It is our most advanced Guardian-HD configuration best suited for large operations, featuring a pre-installed proprietary Windows®-based ViewerSuite software that allows for advanced roll reporting and raw data-logging capabilities for traceability and audits.

The Guardian-HD Elite features a non-contact, non-destructive Near Infrared (NIR) sensor that connects to a traversing frame which continuously scans material across the width of the web for real-time analysis of important quality parameters, helping operators mitigate quality issues caused by improper moisture control, including edge curl and lay flat challenges. This translates to improved quality and consistency, less waste, and a quick return on investment.

Features

- Complete roll recording including measurement value, date, time, length, product name, and others

- Web scan average and individual zone measurements (100 total measurement zones), and up to 100 different recipe codes (materials)

- Automatic sync of roll reports to a local network

- Easily connect to closed-loop control systems or local alarms

- Designated lane and machine direction measurements and trending

- 19” graphical touch-screen display included, with optional enclosure and pedestal

- Easy calibration, operation, and standardization

- Configurations available to monitor and control multiple Guardian-HD systems simultaneously

- Optional Ethernet IP, Modbus TCP/IP interface, or OPC server

Benefits

- Minimize edge curl and lay flat issues with 100% real-time inspection of moisture, coat weight, thickness, and temperature of converting lines

- Decrease manual start-up times by 20%, eliminating the need for time-consuming lab testing and adjustments

- Automatic edge detection feature senses roll width to streamline set-up processes, and realigns to accommodate web drift

- Advanced roll reporting and raw data-logging capabilities for traceability and audits

- Each system can be customized to the width of the web, along with the ability to position the NIR sensor wherever it is needed

- Reduce start-up times and waste by instantly identifying production inefficiencies

- Rugged, sealed industrial frame and linear actuator withstands hot and humid environments common with paper and converting processes

Applications

Rugged NIR Scanning for a Complete Zoned Web

Moisture and coat weight measurements can be made on many substrates including paper, film, foil, textiles, release liners, tags, tapes and labels. The Guardian-HD Web Profiling System is commonly used in the following applications:

- Hot melt & film thickness

- Wet end water based Coat weight

- Dry end organic coat weight

- Exit and inlet dryer moisture

- Re-moisturizers (LAS, steam curtains and water decks)

- Moisture and coatings on paper webs

- PVB & EVA film

- Thickness of hot melts

- Thickness of pressure sensitive adhesives

- Thickness of water-based adhesives

- Paper pulp

- Plastic film thickness

- Biax film

- Exit and inlet dryer moisture measurement

Lineup

How It Works

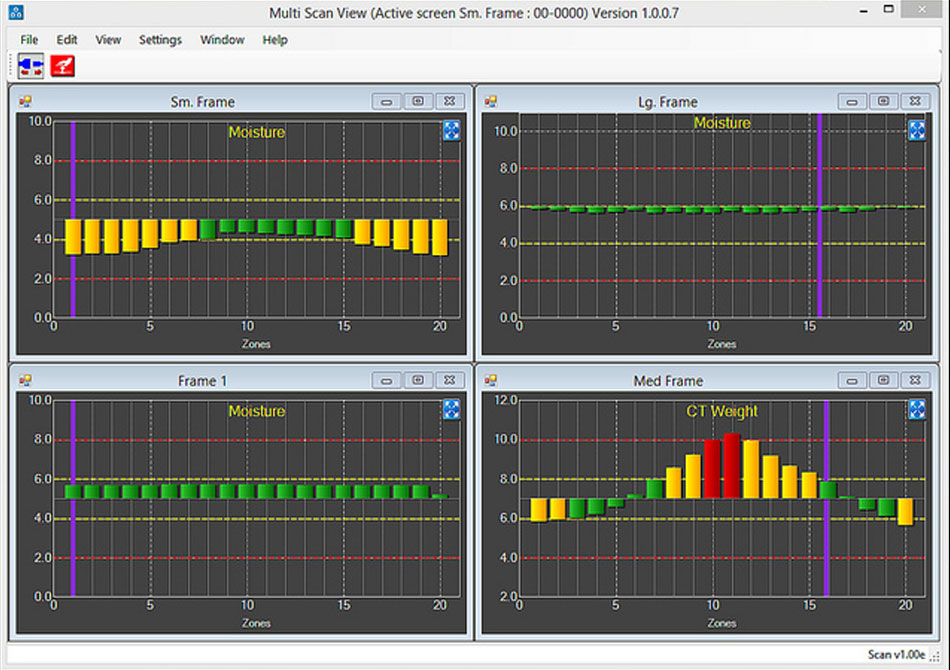

Monitor Multiple Line Profiles From a Single Console

The Guardian-HD Series features an NIR sensor that is connected to a traversing frame to continually scan the full-width of a web profile for moisture and coat weight parameters. Real-time data is presented on an easy-to-understand touchscreen display for cross direction web profiling, lane and machine direction measurements. In some configurations, larger displays with Windows®-based software are available for monitoring multiple line profiles at a single central console.

All Guardian-HD Series configurations allow for USB data-logging with the ability to export to .csv, .xml or .txt file formats.

Each Guardian-HD frame is custom-built for its specific application, and the analysis software can be pre-programmed for specific recipe codes for the material it is analyzing. The NIR sensor can also be positioned in different ways to accommodate reflective surfaces (common with wet-end coating applications) as well as horizontal, vertical, and under-side scanning.

System Components

All components of the Guardian-HD Elite are ruggedized and specified to operate for several years in challenging conditions. Unlike nuclear and X-Ray systems, Guardian-HD Elite does not require costly regulation compliance or safety certifications. Each unit is custom-built for its specific application.

System components include:

- Industrial scanning frame

- An NIR smart sensor

- Local, easy-to-read touch screen display with proprietary Windows®-based ViewerSuite software

- Additional local display touch screen also included

Installation

Food Grade Option

Food Production Applications

The Guardian-HD sensor is available with a food-grade electroless nickel finish and sapphire window (or KEL-F) for food production applications. This allows companies to scan a full array of product entering or exiting a fryer or oven.

Accessories

- Hi / low moisture-only calibration check standards

- Data bus interfaces

- Simultaneous temperature measurement

- 4X alarm relays

- Light stack alarm

Software

Proprietary ViewerSuite Software

Only Guardian-HD Elite users have access to powerful features to monitor and control single or multiple Guardian-HD systems simultaneously. The Windows®-based ViewerSuite software provides enhanced capabilities that allows operators to make on-the-fly adjustments to their settings with ease and manage multiple frames on a single screen. This provides significant productivity savings, helping larger web-converting operations control moisture and coat weight properties of a wide range of materials at once.

Also, for troubleshooting purposes the ViewerSuite software allows for simple customer support from KPM Analytics specialists via Microsoft® TeamViewer.

Proprietary ViewerSuite Software

Only Guardian-HD Elite users have access to powerful features to monitor and control single or multiple Guardian-HD systems simultaneously. The Windows®-based ViewerSuite software provides enhanced capabilities that allows operators to make on-the-fly adjustments to their settings with ease and manage multiple frames on a single screen. This provides significant productivity savings, helping larger web-converting operations control moisture and coat weight properties of a wide range of materials at once.

Also, for troubleshooting purposes the ViewerSuite software allows for simple customer support from KPM Analytics specialists via Microsoft® TeamViewer.

Specifications

Resources